SYSTEMS OF PACKING

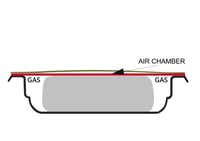

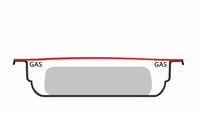

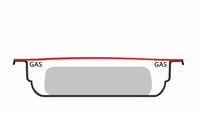

These are the different types of industrial packaging that you will find for any type of food depending on the machine you are going to work with. There are different types of packaging for thermoforming machines, cardboard thermoformers, traysealers, cardboard traysealers, vacuum and flow machines.

If you have any other questions, you can contact our customer service team where you will get personalized advice.

The food packaging method is not only important to achieve an optimal final result in terms of product presentation, but it is also one of the variables that will have a significant impact on its conservation.

Pressure, temperature and time have different effects depending on the technique used:

- Temperature – When hot filling, it is important to remember that most flexible materials, such as PET containers, have a maximum transition temperature of around 70°C, so particular approaches must be used to minimize warping both during and after filling. Low temperatures, on the other hand, are used in high pressure packing.

- Time: This parameter has a significant impact on systems such as packaging in a protective atmosphere, where the introduction of gases after the elimination of oxygen must be very fast, as well as high pressure packaging, where the content can deform if the hydrostatic pressure is too high. elderly. Performed over a longer period of time than necessary. Also, in hot filling, hot-tack or heat sealing strength will affect the optimization of filling speed.

- Finally, pressure will be critical in systems like high pressure packaging, where pressure needs to be delivered evenly throughout the food and in all directions.

- Weld Time – The amount of time the weld plate is held against the material determines rate, peelability, and tightness, among other important factors in proper packaging.

In addition to temperature, time and pressure, a factor such as food protection must be considered in any packaging process, which is usually a combination of needs to prevent deterioration, leakage, alteration, contamination, dehydration, compression, etc. barrier against oxygen, against water vapour, against bacteria, and a long etcetera.

?

Can´t find what you´re looking for?

Don´t worry, we are sure to have a solution for your business.